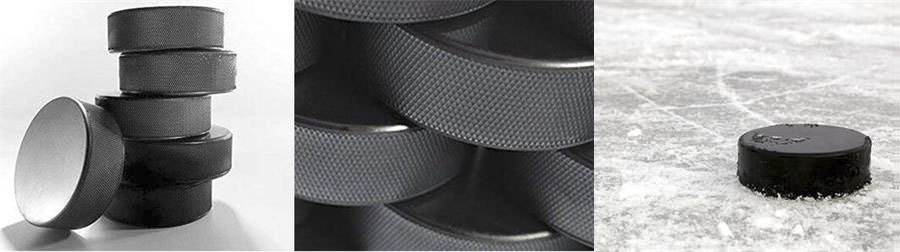

HOCKEY PUCKS

Made using the highest quality vulcanized rubber.

All these models can be printed for best individual customization.

BLACK – OFFICIAL

Suitable for practice and official games, for ice hockey players of all ages and skill levels. NHL level quality with textured, knurled sidewalls for improved adherence to hockey stick blade. Remarkable flatness, hardness and smooth surface quality for consistent, powerful and accurate shots and passes.

Tested in the laboratory.

Dimensions: 3″ diameter (7.62 cm) by 1″ thick (2.54 cm); Weight: 165g

NHL official size and weight

WHITE

A great training tool for goalies to develop their reaction time, as they have to focus more on the puck.

Standardized performance that can withstand intense use.

Tested for durability.

Dimensions: 3″ diameter (7.62 cm) by 1″ thick (2.54 cm); Weight: 165g

ORANGE – WEIGHTED

The heavy weight puck is used to strenghten all aspects of stickhandling techniques. This puck is designed to improve your muscle strength, quickness and power. Ideal for training the player of all ages and abilities.

Dimension: 3″ diameter (7.62 cm) by 1″ thick (2.54 cm); Weight: 275g

BLUE – LIGHTWEIGHT

The lightweight puck is ideal for youth players to improve their coordination, quickness and overall speed.

Ideal puck for beginners.

Dimension: 3″ diameter (7.62 cm) by 1″ thick (2.54 cm); Weight: 125g

BLACK – JUNIOR

A smaller, light puck intended for ice hockey of the youth in Europe.

Meets strict hardess, weight, rebound elasticity and surface quality standards.

Dimensions: 2.36″ diameter (6 cm) by 0.79″ thick (2 cm); Weight: 95g

PROMOTIONAL PUCKS

Pucks made not only for promoting ice hockey issues, but also used for promotional purposes concerning industry, cultural events or some region. Ideal for use in recreational context.

Dimensions: 3″ diameter (7.62 cm) by 1″ thick (2.54 cm); Weight: 165g

PACKAGING

100 Pieces Per Carton

CERTIFICATION

Our pucks currently meet the strict criteria of international norms.

CAN/CSA Z 262.4-97